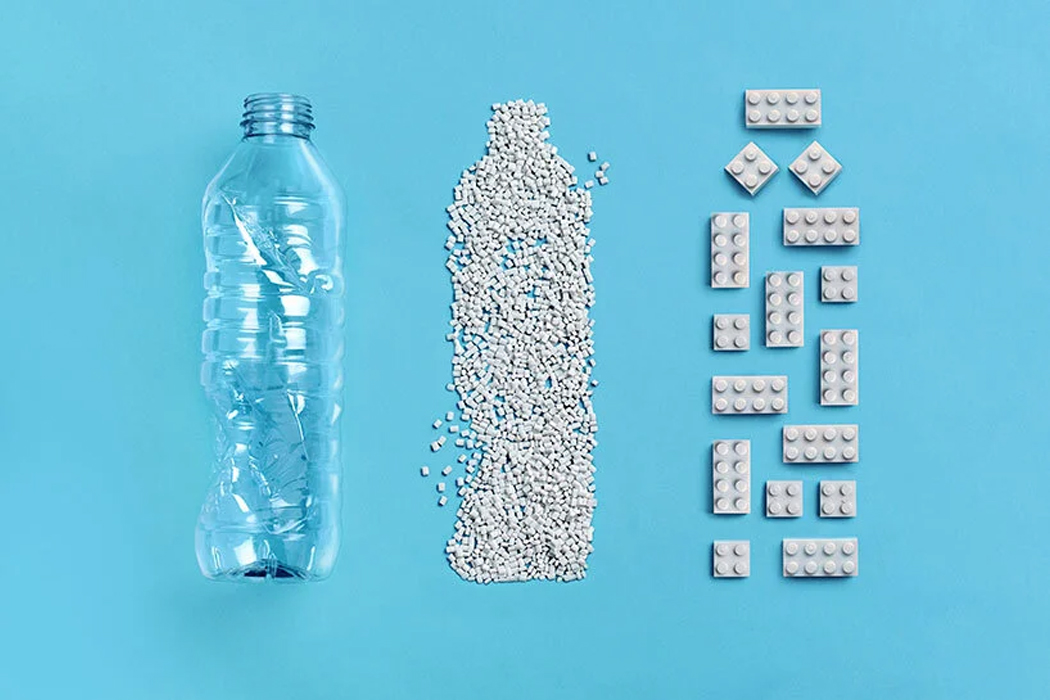

Since 2018, LEGO has been making strides towards sustainability initiatives including removing single-use plastic from their boxes and producing specialty elements from bio-polyethylene, a natural polymer sourced from sugarcane. Today, the iconic toy company reveals its latest sustainability effort, a prototype brick produced from recycled PET plastic. Derived from discarded plastic bottles, LEGO’s new sustainable prototype marks the culmination of three years worth of testing over 250 variations of PET plastics. The result, a LEGO brick constructed entirely from recycled materials that meet an array of different requirements, including safety, quality, play, and perhaps most exciting, clutch power.

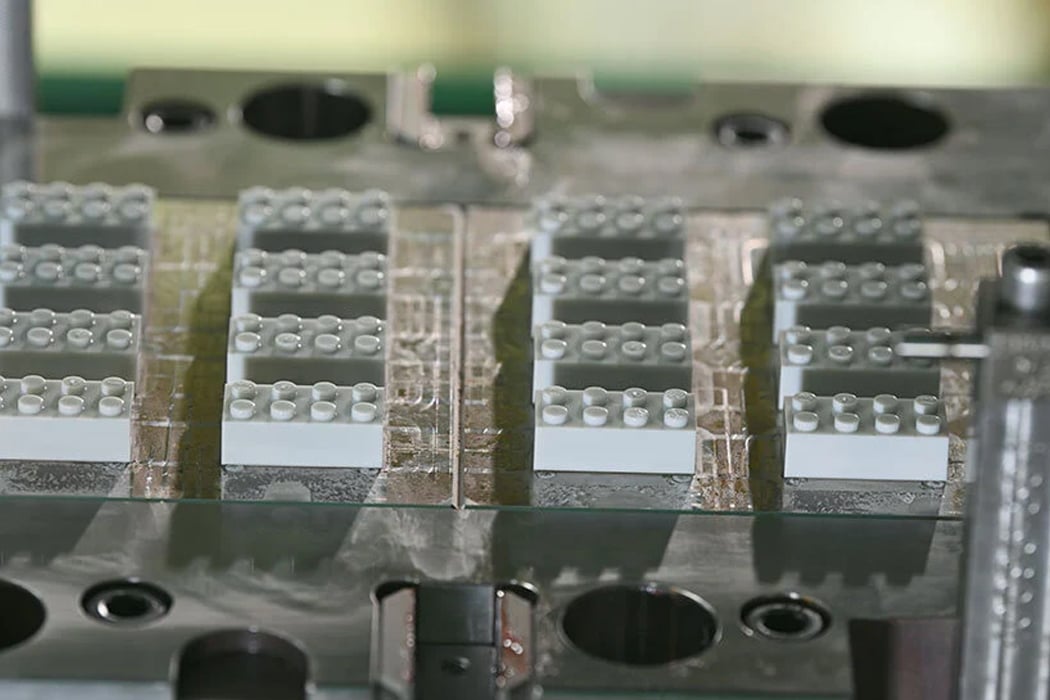

Following a year of testing and reassessing of different PET formulations, LEGO will consider moving onto a pilot production phase, which would bring the recycled LEGO blocks into product boxes to hit the shelves for purchase. Sourced from a single one-liter PET plastic bottle, LEGO’s patent-pending PET formulation can produce ten 2×4 bricks, using a custom compounding method to ensure classic LEGO structure and secure linkage. Currently, the prototype is a blend of recycled PET plastics and additives that work to strengthen the recycled plastic and in turn meet specialized LEGO requirements. Vetted by the USA’s Food and Drug Administration (FDA) as well as the European Food and Safety Authority (EFSA), LEGO’s new recycled composition guarantees the same quality building blocks we’ve come to expect from the mega toy company.

Speaking on the brand’s latest step towards producing sustainable and recycled building blocks and the prototype’s proximity to pre-existing bricks, LEGO’s Vice President of Environmental Responsibility notes, “We are super excited about this breakthrough. The biggest challenge on our sustainability journey is rethinking and innovating new materials that are as durable, strong, and high quality as our existing bricks — and fit with LEGO elements made over the past 60 years. With this prototype, we’re able to showcase the progress we’re making.”

Designer: LEGO

From a single 10-liter PET plastic bottle, ten 2×4 LEGO bricks can be produced.

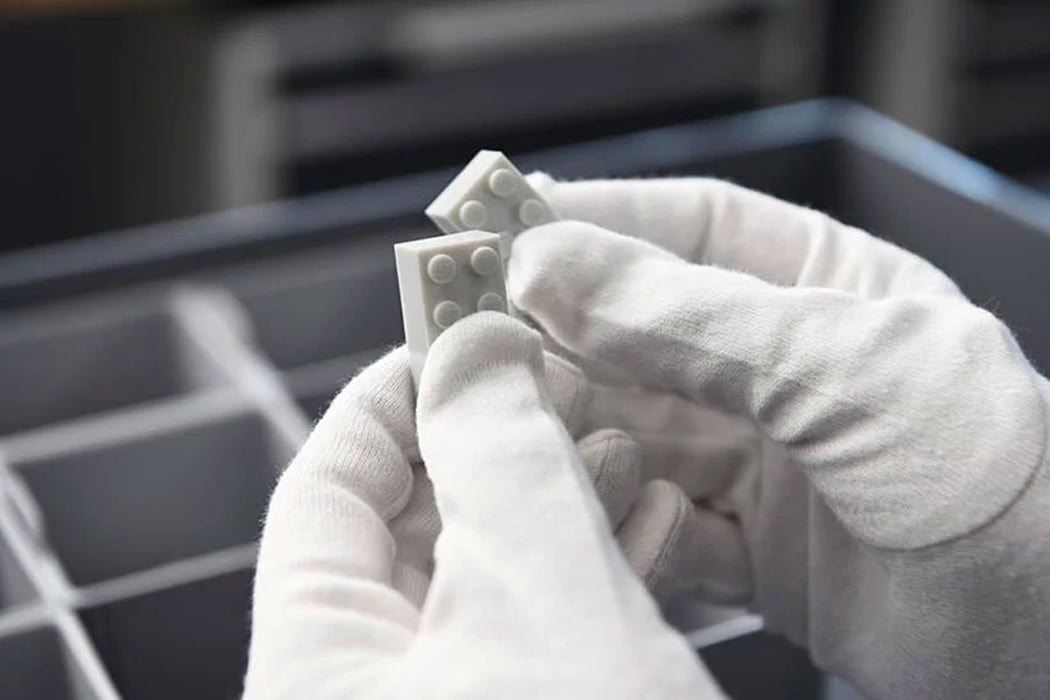

Complete with the same quality as pre-existing LEGO bricks, the new recycled bricks meet every safety, play, and clutch power requirement.

Following three years worth of testing, LEGO finally found an ideal PET formulation for its new recycled brick prototype.

By incorporating strengthening additives, LEGO’s recycled prototype maintains the same quality and strength as pre-existing LEGO bricks.

via https://ift.tt/2nqSsIm

Post a Comment

Note: Only a member of this blog may post a comment.