The technique isn’t too different from making papier-mache products, and all you need is a set of molds to really compress the cardboard pulp, creating a robust, durable product.

The response around the ‘anti-sex’ Olympic beds has been pretty amusing if you ask me. Cardboard’s definitely got a really bad rap as a material, because of its ‘packaging’ status. Paper can actually be pretty durable and robust if you get your physics right (try whacking yourself on the head with a hard-bound book); something Irish gymnast Rhys McClenaghan even demonstrated by jumping up and down on the Olympic village beds to prove their durability. YouTube-based creator XYZAidan’s worked out his own way of recycling cardboard into durable products too, by shredding old corrugated board panels and turning them into a pulp, which he then proceeded to cast into 3D-printed molds. The result is a lot like engineered wood, except made from disintegrated cardboard instead of sawdust. It’s just as durable, and if your molds are designed properly, the end product can come out looking pretty clean and finished. You can check out the process video above, or scroll down to get access to the mold 3D files that XYZAidan made available on his Thingiverse page.

Creator: XYZAidan

If you’re familiar with how injection-molded plastic products are made, the process for working with cardboard pulp is rather similar. You’ve got liquidized raw materials that fit inside a mold, which helps form and compress the fluid mass into a tightly packed design. Once ready, the mold separates into its different parts, releasing the final product. XYZAidan started by first preparing his raw materials. Grabbing any cardboard he could find and finely shredding it in a paper shredder, XYZAidan then proceeded to blend the cardboard strips with water and a water-soluble binder. To keep things eco-friendly and biodegradable, he opted against synthetic PVA glue for a more natural rice paste, made by mushing cooked rice in water over a stovetop to create a starchy pulp that would hold the cardboard fibers together in the mold.

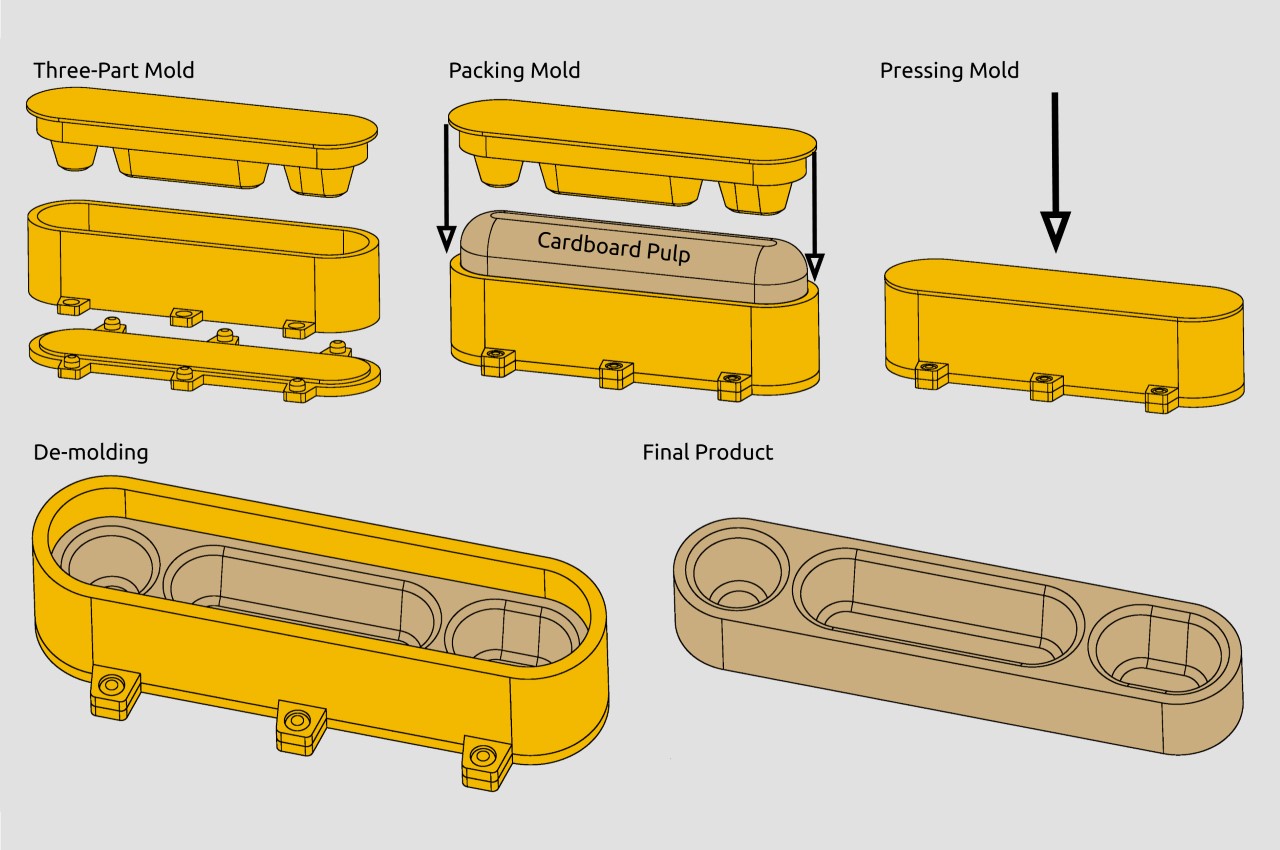

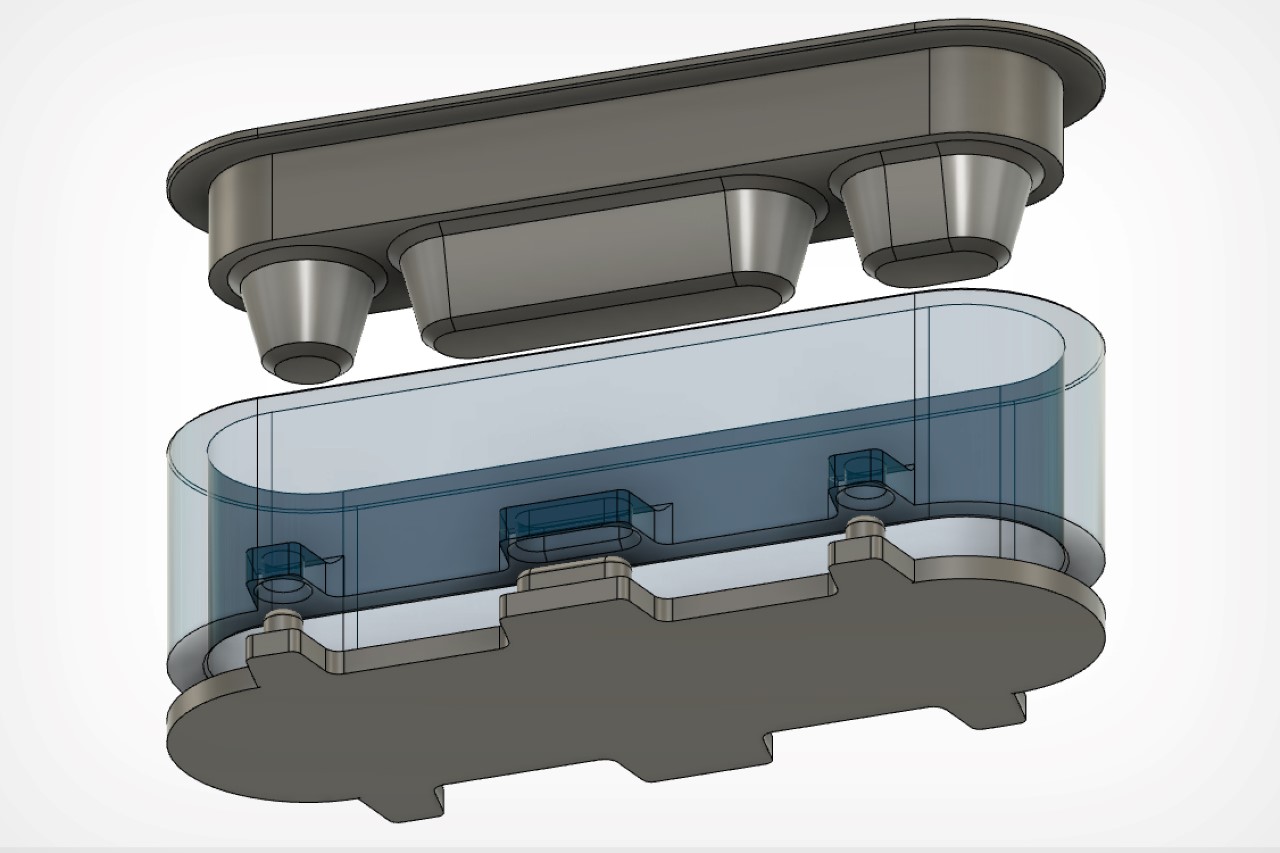

Depending on the kind of product you want to make with your recycled cardboard, XYZAidan recommends using 3 or more mold parts, so that the product can release from the mold easily. Given cardboard’s fibrous, absorbent nature, the product tends to expand inside the mold, so you best create a mold that’s easy to disassemble, or you’ll either break your product or your mold in the de-molding process. XYZAidan took to a 3D printer to make his molds, ensuring that they were robust and had a strong inner support structure since the mold would need to be clamped together.

Once everything’s ready, just assemble your mold and pour the liquid pulp in. There’s no fixed ratio or volume, and a lot of it has to be done by eye. You’ll need to over-fill the mold, since the pulp has to be compressed into shape, and you’ll also need to have separate drainage holes for the water to exit through. Just clamp your mold in shape and leave it for a day, allowing the cardboard pulp to set in shape.

Once you’ve let an entire 24 hours pass (add a few more hours for good measure if you’re doing this in the monsoons), disassemble your mold and your product should be relatively set and easy to pull out. It’ll still be slightly wet, which means you’ll need to leave it out for another day to completely let it dry. Once dried, just trim the flared cardboard bits and you’ve got a final recycled cardboard product that’s robust, solid, yet incredibly lightweight. Depending on the quality of your mold, it’s possible that your product could have those 3D printed step-lines or layers too (see below). The best solution is to either to sand down your mold or sandpaper your products after they’ve completely dried. Then just finish them off with a layer of paint and you’re ready!

The possibilities are absolutely endless. You could create shoes for yourself, stationery-holders like pen-stands or cups for paper clips, robust laptop stands, or even textured sound-absorbing panels to mount on your walls! XYZAidan’s been kind enough to make all his 3D printing mold-designs available for free on Thingiverse, and you can even visit his YouTube channel to see what else he’s been up to.

via https://ift.tt/2nqSsIm

Post a Comment

Note: Only a member of this blog may post a comment.