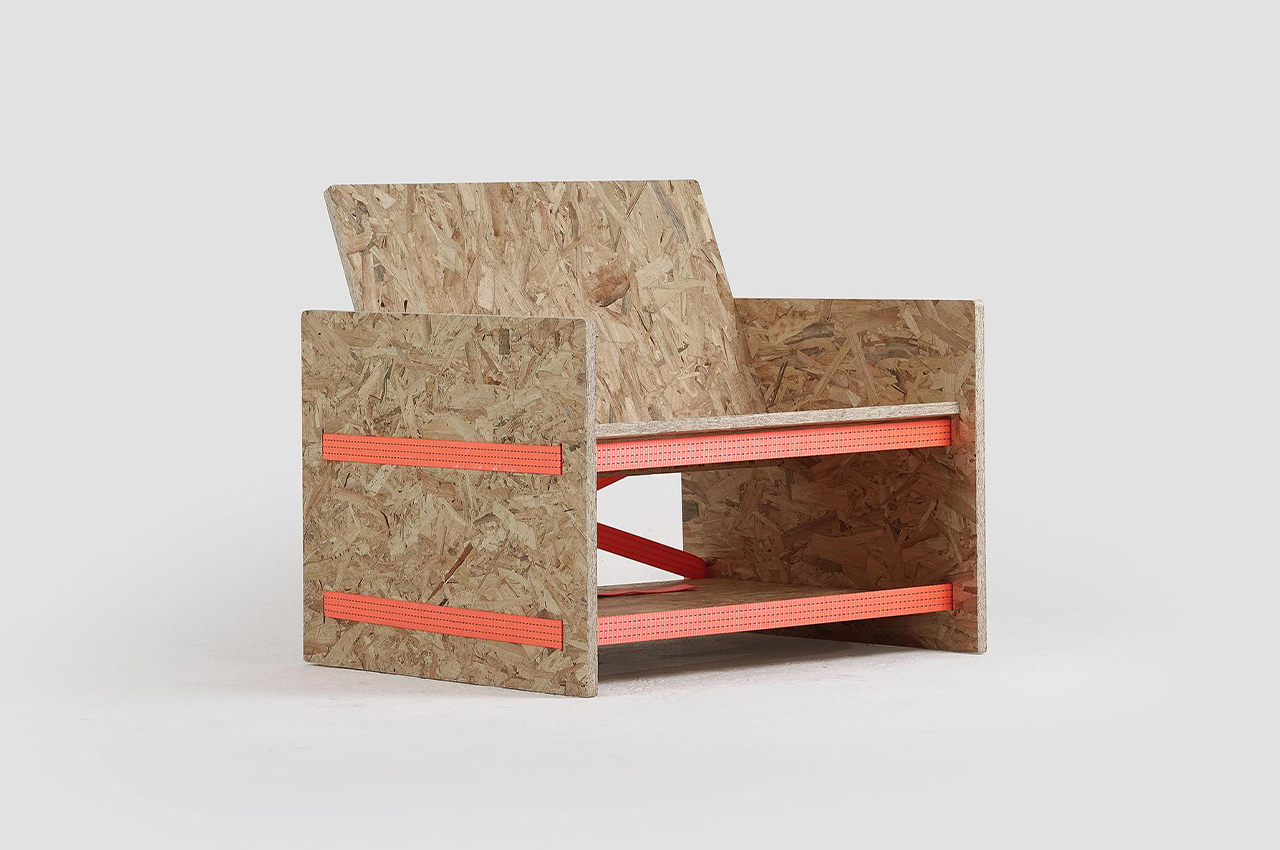

The TEMP chair has been designed as an eco-focused seating solution that makes use of an unlikely material to blend packaging and assembly into one piece. The chair is made by cutting OSB (oriented strand board) and is assembled by tying a single cargo strap with ratchets. The luggage strap, which can withstand more than 700kg, makes for a super sturdy chair without the use of screws, glue, or any hardware!

OSB is stronger and more waterproof than plywood. It is a versatile, cost-effective, and environmentally friendly alternative manufactured by compressing precisely engineered strands of woods with exterior resins at high temperatures to create an incredibly strong panel.

The cargo strap is also used to wrap the panels effectively reducing packaging for the chair. The five panels that make up the chair can be grouped together, and one panel has a handle, so it can be easily moved while packed.

It is designed to be wider than the existing chair, so you can take a break in various postures, and the lower part of the seat can be used as a storage space.

The reasonably priced OSB has enough strength to make up the chair, and the wood chip pattern makes it hard to see scratches, so it could be shipped without additional packaging.

Joo Hoyoung said, “I ordered plywood cut from a carpentry shop. I tied the cut plywood with a cargo string to bring home. When I came home, I untied the string, put the plywood in the right place, and tied the string again. I am sitting in the chair that has been completed just like that and writing this!” – could it BE any simpler?!

Designer: Joo Hoyoung

via https://ift.tt/2nqSsIm

Post a Comment

Note: Only a member of this blog may post a comment.